Siete Holiday Cards

Ultimate Goal

Deliver 2,000 custom wooden holiday cards on a near-impossible timeline.

Skills Acquired

Production Skills

- • Scaling production from prototypes to thousands of units

- • Jig design in CAD for manufacturing efficiency

Process Skills

- • Workflow engineering for repeatable processes

- • Preventative machine maintenance under load

Project Overview

Siete was my first real step into large-scale production. A client needed 2,000 laser-cut holiday cards, designed and manufactured in less than a month. The quantity was intimidating — I had never produced anything at that scale before — but I took it on as a challenge to see if I could translate my maker skills into true production workflows.

Project Timeline

- • Design finalized: 1 week

- • Production time: 3 weeks

- • Total quantity: 2,000 units

- • Material: Laser-cut wood

Key Metrics

- • Production rate: 9 cards per 1h 36min run

- • Changeover time: ~1 minute between jobs

- • Daily schedule: Wake up to 1am continuous cycles

- • Result: All 2,000 delivered on time

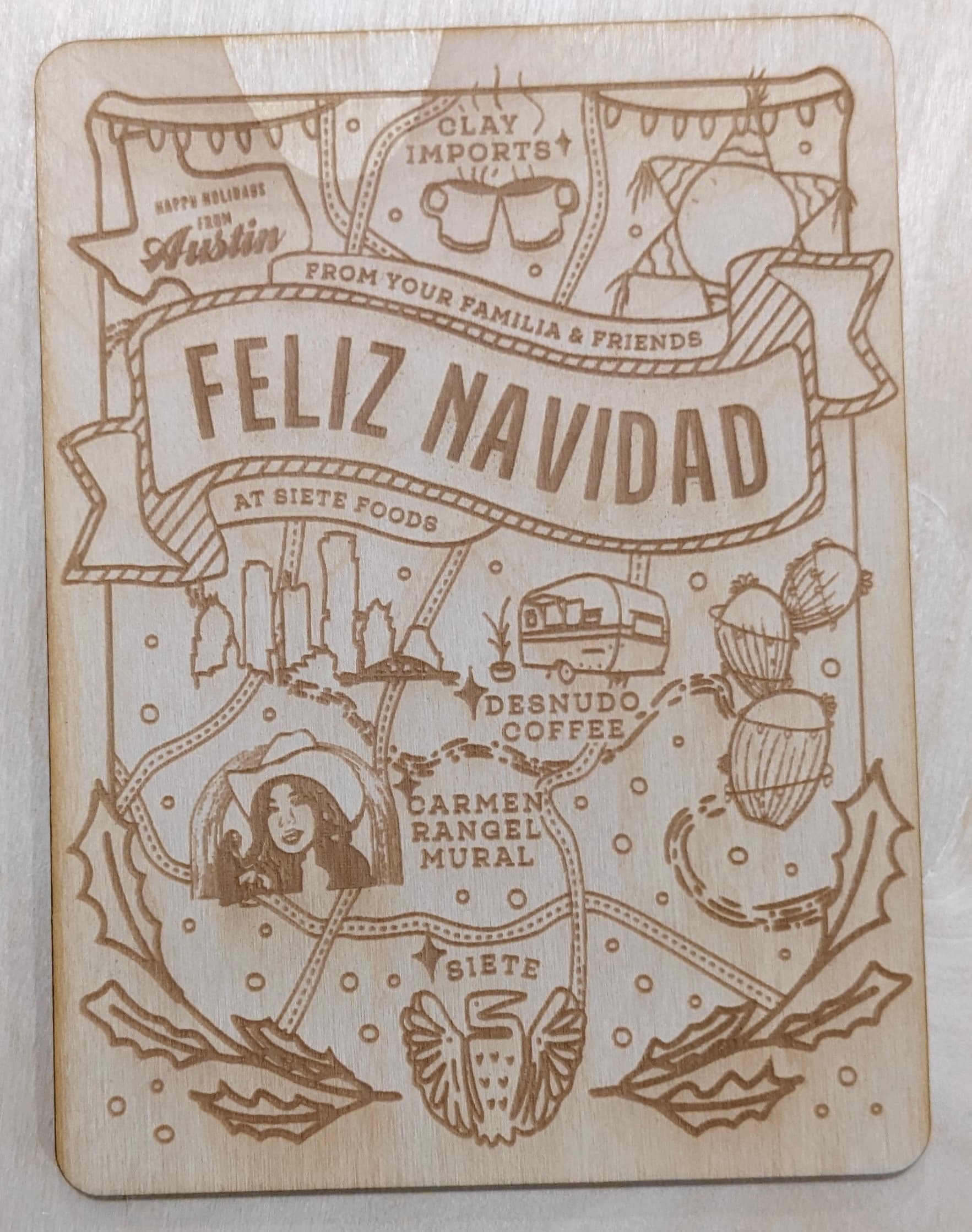

The Finished Holiday Card

The intricate laser-cut design features Austin landmarks, Siete branding, and festive elements, all precisely cut from 1/8" plywood.

Key Challenges

Extremely tight turnaround (design finalized in 1 week, production in 3)

Scaling from "one-off craft" to 2,000 identical units

Preventing flashback while maximizing material use

Maintaining machine quality over long production days

Solutions & Innovations

Custom Jigs

I mapped the laser bed in CAD and designed fixtures that held the wood rigid, elevated off the bed to avoid flashback, while squeezing maximum parts per sheet. The jigs were 3D printed in-house.

Production Workflow

Each run took 1 hour and 36 minutes for 9 cards. Thanks to the jigs, changeover between jobs was about one minute, so I could run continuous cycles from the moment I woke up until 1am.

Machine Maintenance

Cleaning became part of the workflow — I had to service the laser lens daily to fight residue buildup and keep engraving quality consistent.

Outcome & Results

All 2,000 cards were delivered on time. Individually, each card was simple to make, but the engineering that went into enabling production at this scale was the real achievement. It proved I could move from being a maker of one-offs to an engineer of repeatable processes.